ROOTS BLOWERS

FP SPOMAX S.A. is the only Polish manufacturer of Roots blowers.

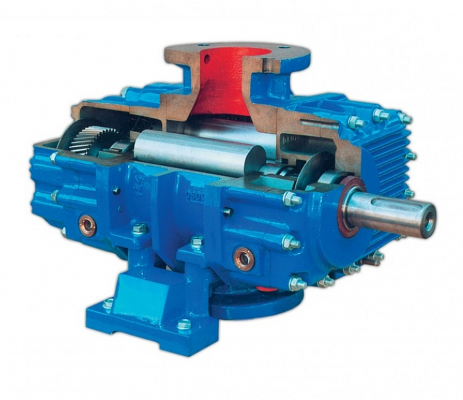

FP SPOMAX SA is the only Polish manufacturer of Roots blowers. It offers high-quality products that have been appreciated by numerous customers. The company is a leading supplier of blowers on the Polish market. It also has a strong position in the US and Canada. Roots type blowers are positive displacement machines (with low pressures and high flows). They can work in the processes of compression (as a blower) and suction (as a vacuum pump). They are designed to generate continuous overpressure or underpressure of air or inert gases. They are used wherever the carrier of the transported material must be free from oil contamination.

FP SPOMAX SA supplies compression stages and complete blower units. The company offers blowers with capacity from 20 to 8460 [m3 / h] and pressure up to 1100 mbar. Depending on the size, the blowers are produced in many construction versions, in 15 sizes (from DR80 to DR1300) and with various equipment.

Currently blowers of the following types are produced:

DR80, DR91, DR92, DR100, DR101, DR102, DR112, DR113, DR114, DR124, DR125, DR126, DR127,DR128, DR130, DR210, DR240, DR250, DR260, DR270, DR500, DR700, DR900, DR1100, DR1200, DR1300

Manufactured blowers are used for:

- aeration of activated sludge chambers in sewage treatment plants

- aeration of sand traps

- water treatment apparatus

- medicine: to increase pressure in normo-baric chambers

- air supply to blast furnaces and lime burning

- napowietrzania materiałów sypkich i złóż fluidalnych

- low-pressure pneumatic transport (pressing and suction) of loose materials (flour, cement, lime, biomass, PVC granules, ash, etc.)

- central vacuum systems

- vacuum systems in paper machines

- suction and discharge systems of inert gases (in special versions, also aggressive and explosive)

- aeration of fish ponds

- blowing in combustion processes

- vacuum drying systems

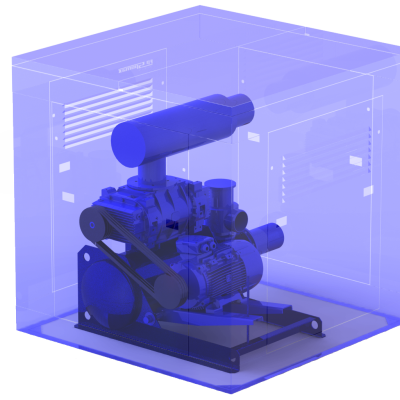

Standard delivery scope of the Roots-type blower unit:

- blower unit - compression ratio

- electric engine

- support frame with tensioning slide

- belt transmission / clutch drive

- gear casing (depending on the blower version)

- air filter

- inlet noise silencer

- exhaust noise silencer

- overload valve

- check valve

Firma FP SPOMAX S.A. produkuje również dmuchawy w wykonaniach specjalnych

Blower unit for explosive gases

It is designed for suction or delivery of e.g. methane, hydrogen or biogas. It is made in an explosion-proof version and equipped with special sealing solutions of the compression chamber, output of the driving piston and connections on the suction and discharge.

Two-stage blower unit

Thanks to the use of two compression stages, a pressure increase of up to two bar is achieved.

Blower unit with multi-storey construction

There is a possibility of building two blowers in two levels. Stacked blowers can be equipped with soundproof covers appropriate to their design.

Compression levels (blowers) for installation on tank trucks

They are used as overpressure or underpressure stations for pneumatic loading or unloading of road tankers transporting products such as: flour, grain, feed.

Suction-pressure blower unit

Depending on the direction of rotation of the pistons, it can work as a suction or forcing and supply air to one or two independent pipelines. Used in technological processes requiring overpressure or underpressure up to 0.05MPa.

Compact aggregates

- modernized design

- smaller dimensions

- less energy consumption

- automatic tensioning of drive belts

- new structure of the sound-absorbing casing (easier assembly)

- blower control module

Firma FP SPOMAX S.A. oferuje także REMONTY remonty dmuchaw typu roots innych producentów oraz serwis dmuchaw u klienta.

The company sells spare parts for blowers.

FP SPOMAX S.A. zapewnia również kompleksową obsługę obiektów.

Obudowa dźwiękochłonna

Obudowa dzięki swej konstrukcji wykorzystującej specjalne materiały dźwiękochłonne oraz tłumiki szczelinowe spełnia rolę izolatora dźwięków pracującej dmuchawy. Wentylator zapewnia właściwą temperaturę pracy dmuchawy. W przypadku otwarcia zaworu przeciążeniowego następuje odprowadzenie uchodzącego z niego powietrza przez tłumik szczelinowy poza osłonę. Proponowane osłony dźwiękochłonne wyciszają pracę dmuchaw od 16+25 (±2) dBA w zależności od zastosowanych materiałów wygłuszających.